Product classification

Contact Us

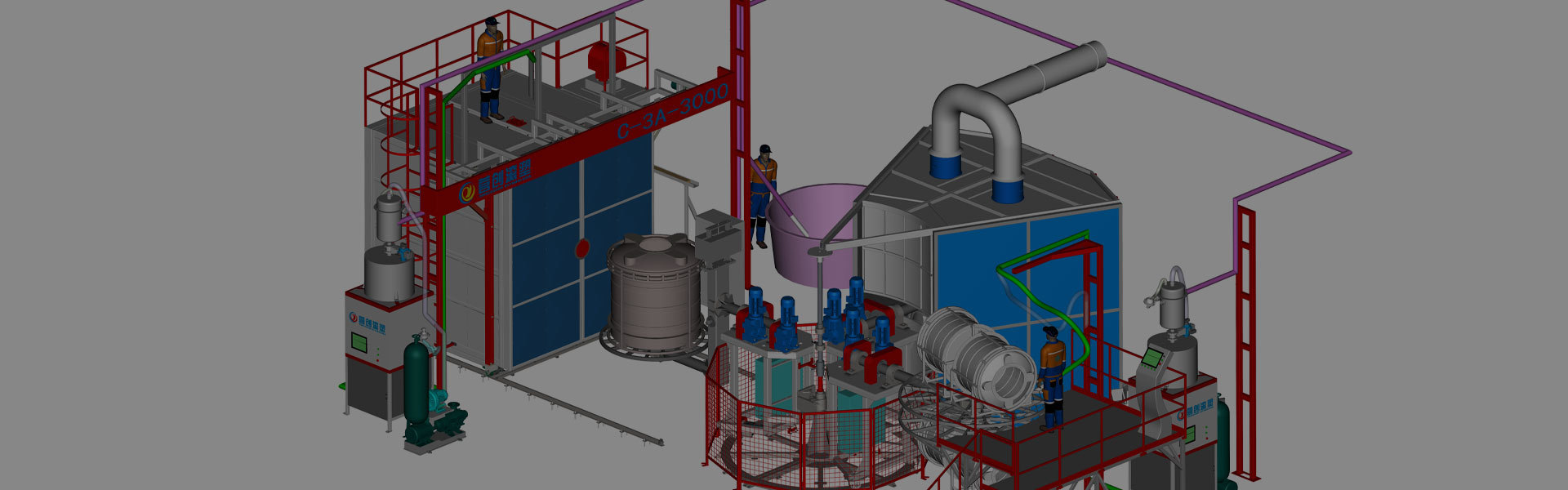

80L vacuum box

The company mainly focuses on rotomolding equipment, rotomolding moulds and rotomolding products, and customizes the design according to each customer's needs in order to achieve both service and quality.

Product Details

What is rotational molding?

Rotational molding is a method of hollow forming using thermoplastic materials, suitable for most large and medium-sized plastic products and composite products, with good product quality and low investment costs.

The basic process includes the following steps:

1. Pour a certain amount of powder raw material into the mold and combine the mold using screws or clamps.

2. Heat the mold and rotate it at 360 degrees in an oven; the raw material melts within 230-300 degrees Celsius in the mold, evenly adhering to the inner surface of the mold to form the desired shape; the heating time depends on the material, shape, type, and weight of the mold.

3. After reaching a certain time and completing the heating, the arm moves to the cooling station to start cooling, usually using air cooling and water mist cooling. When the surface of the mold cools to between 80-90 degrees Celsius, the rotation of the arm stops, the mold is opened, and the product completes the molding process.

Advantages of rotational molding

1. Low cost of rotational molding molds: For products of the same specification, the cost of rotational molding molds is about 1/3 to 1/4 of that of blow molding and injection molding molds.

2. Good edge strength of rotational molding products; rotational molding can achieve a thickness of more than 5 millimeters at the edges of products, completely solving the problem of thin edges in hollow products.

3. Rotational molding can accommodate various accessories.

4. The shape of rotational molding products can be very complex, with a thickness of more than 5 millimeters.

5. Rotational molding can produce fully sealed products.

6. Rotational molding products can be filled with foam materials for insulation.

7. No need to adjust the mold; the wall thickness of rotational molding products can be freely adjusted (over 2mm).

8. The products are hollow and seamless, but the wall thickness can be adjusted to give the products high strength.

9. Various surface pattern treatments can be provided, producing products in various colors, and can be treated for UV resistance and aging.

10. Rotational molding is suitable for large hollow plastic products (for example, water towers, steel-lined plastics, etc.)

The company to advanced technology and services as the core, adhere to scientific and technological innovation, “Yihua” brand has the domestic forefront of the rotomolding industry in the talent and technology team, rotomolding equipment technology at the forefront of the domestic level, the company has a senior engineer specializing in mechanical design for more than 20 years, engaged in the design of industrial automation control systems for more than 15 years, industrial control experts. The company has senior engineers who have specialized in mechanical design for more than 20 years and industrial control experts who have been engaged in industrial automation control system design for more than 15 years.The company mainly focuses on rotomolding equipments, rotomolding moulds and rotomolding products, and customized design according to each customer's demand, in order to achieve the service and quality coexist.

Keywords: rotational molding products, rotational molding equipment, rotational molding molds

Previous Page

Next

Previous Page

Next Page

Online message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.